An Adjustable Register Rough-in Frame

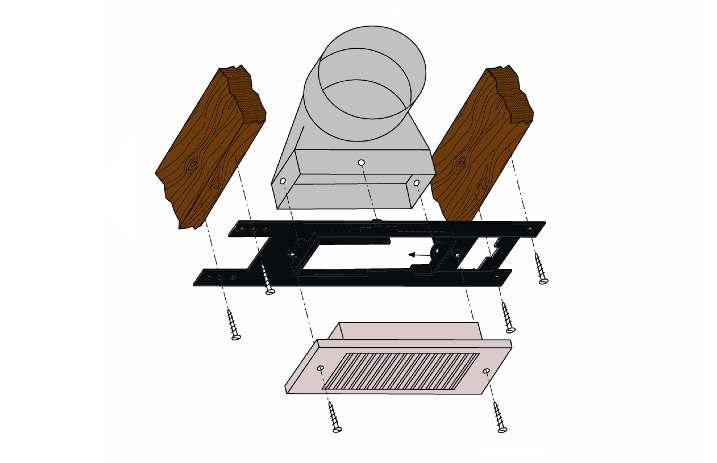

The H frame is used to install registers in residential and light commercial applications. It holds register boots and grilles that are 4" or 6" wide and both frames adjust from 8" to 14" in length. The 6" frame is also used as a return air frame with "locks" for the slider to keep it from moving out of position. Contractors should attach the boot to the H frame on a flat surface by placing the rectangular end of the boot into the open area in the middle of the H frame. Then, move the sliding component of the frame until it is flush against the boot. Attach the boot to the H frame by inserting sheet metal screws into the upright tabs on the H frame on either side of the boot. Hold the entire assembly against the joists and attach to the joists using screws or nails through the elongated legs of the H frame. Contractors may use the pre-drilled holes, but that is not a requirement. Once the frame is in place, the duct may be attached to the boot. Dry wall is then applied around the H frame, covering the frame. Finally, the register grille screws are inserted into the self-threading plastic mounts on the H frame.

Easy, fast, done!

1 or 2 part numbers instead of 8-10, reducing inventory, handling, paperwork and mistakes (i.e. ordering the wrong product or having the wrong product at the job site).

Our high impact plastic is heat/cold/UV resistant and offers an installation with no cuts, noise, or condensation....Sheet metal frames cause noise/vibration, cuts to installers, often bend out of shape (scrape cost), and have a higher material cost.

The H installs in seconds by simply inserting sheet metal screws through the tabs into the boot, then nailing the entire assembly into place against the joists. Metal frames require "crimping" the boot into place on the frame or spot welding to connect the components together. They often come apart and have to be reassembled.

The H frame provides a secure connection of components. The register grille pushes the base of the metal boot against the H frame, providing a tight seal with correct dimensions and no CFM loss.

The H frame installs straight every time. Metal frames are often crooked, and it's difficult to determine this until the finish work is complete. If a homeowner or builder wants the work redone, the entire area must be refinished (drywall, frame, grille), leading to excessive labor costs.

Industry professionals really appreciate the H frame installation. They know it is a quality job that will eliminate homeowner issues.

The H frame eliminates expensive call backs for loose or fallen grilles, crooked installations, noise/vibration or rough-ins damaged or knocked out of position by other subcontractors . An average call back involves scheduling, materials, trip time (out and back) and time on the job, which can be very expensive.

The H frame provides secure, self-threading mounts for grille screws. Homeowners who remove the grille for color change, cleaning, or duct cleaning can easily reattach the grille (the mounts are visible and do not strip). Metal frames, on the other hand, do not provide a secure hold for the grille. The screws often loosen or strip from the dry wall or sheet metal causing loose grilles, complaints, and expensive call backs.

Dry wall contractors often completely cover register openings installed with a metal frame. Or, when they do cut the opening for the register, the opening will be too wide or too narrow based on the curve of the metal boot. All of this adds up to excessive labor time to find and/or repair the opening. The H frame, on the other hand, has rigid walls that the dry wall contractor will use to cut the opening. Any cutting tool such as a zip saw glides easily along these walls to provide a perfect rectangular cut.

Contractors are under constant pressure to get the job done faster AND better. Paramount Concepts, Ltd. and The Habegger Corp. make it happen.

Habegger's Indianapolis Branch was an early adopter of the Paramount H adjustable register installation frames. They recognized this new technology could deliver substantial savings for contractors, and they became one of the first companies to market the product.

Partnership according to Ken Hurst, Regional Parts Manager, who says, "We had a lot of help from Paramount Concepts on direct contact to the contractors. Paramount Concepts is very easy to work with, and very willing to do whatever it takes."

It also helps to have a great salesperson. Brett Myers, Territory Manager with Habegger Indianapolis, makes it sound easy. According to Brett "I just took it out to the job sites and let the customers play with it. The Paramount H is one of the few products we have that will actually sell itself."

We all know it's not that easy. It takes skilled distribution partners like the pros at all Habegger locations. It takes a committed vendor, and Brett believes "Paramount Concepts has been, to say the least, awesome. It's been outstanding."

The proof is in the field, with contractors, and that's where Brett prefers to sell the Paramount H. "We have been successful with the Paramount H because the customer can see the payback instantly."

"I have a customer who now does all of their boots in a 6,000 square foot house in 20 minutes, instead of a whole day," says Brett. "I started having customers sell me on the product."

Innovation also has to be affordable. According to Ken, "Paramount has been very helpful at putting us at [price] points in the market where we need to be. You [Paramount Concepts] have been very tuned to the needs of the customer."

Will the H cause a bump in the drywall when it is covered?

No, this has been extensively tested and used with no issues... in fact, the H frame is the same thickness as the S lock brackets used with sheet metal frames.

What sizes will the H-4 and H-6 accommodate?

Both frames will adjust from 8" to 14" in length.

Why does the H-6 have "locks" for the slider but the H-4 does not?

These locks provide added strength and stability for the larger 6" wide boot. They also prevent the slider from moving in applications where the H is used as a return air frame with no boot. There are no applications of a 4" return with no boot, so the locks are not needed on the H-4.

Why should I use the H instead of a sheet metal frame or a boot with "ears"?

Will this product crack in the cold like other plastic products?

No, the H is made of a High Impact Polystyrene and the J of a CoPolymer Polypropolene... both have been tested for cold, heat, and UV resistance.

Are these products UL or NFPA certified?

Both the H and J have been presented to UL (Underwriter's Laboratory) and NFPA (National Fire Protection Association). Because the products play a supportive role not central to the transfer of heated or cooled air, certification is not necessary.