A Versatile Hanger for Flexible Duct

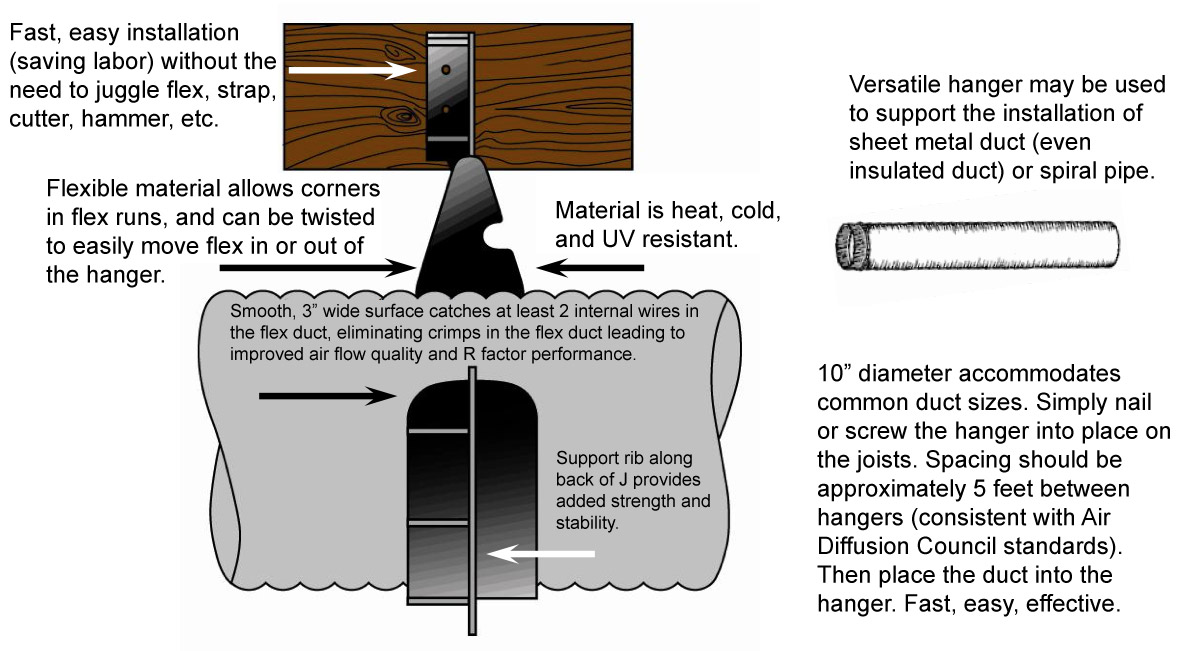

The J offers a fast installation, saving labor time and cost. Simply nail the hangers onto the joists approximately five feet apart, then place the duct into the saddle portion of the J. Strap often requires two installers who need to wrestle with flex, strap, cutters, and a nail/staple gun. This leads to excessive installation time and cost.

Our smooth, 3" wide surface will support at least 2 of the helical wires inside the flex duct. This allows smooth and consistent air flow with no compression (sweat) of the insulation. Strap causes crimps in the flex duct, reducing air flow quality and insulation performance. This leads to complaints and expensive call backs.

Industry professionals really appreciate a J hanger installation. They know it is a quality job that will eliminate homeowner issues. With the J hanger, the result is a better quality installation at a lower cost.

The J eliminates the expensive call backs caused by strap installations (air flow restriction due to crimping, sweat due to insulation compression, and corrosion / replacement).

Contractors who need access to a particular space can easily move the flex duct out of the J, then place it back into the J when finished. With strap, it is often cut down, requiring additional labor time and expense to re-hang.

The flexible material of the J allows it to bend to accommodate corners in the flex duct run. It can even be twisted completely down for easy use in crawl space applications. Straps will lead to excessive crimping and air flow problems in these situations.

The support rib along the underside of the J provides excellent weight bearing capability. This allows the J to be used for spiral pipe, metal pipe (including insulated), trunk lines in high velocity systems, and many contractors run their line set with the flex duct through the J hanger.

Our co-polymer plastic is heat, cold, and UV resistant. Strapping material often corrodes and requires replacement (call backs), and requires cutting lengths of strap which is time consuming and can cause injuries.

What is the half circle cut into the J?

This is where a water line runs through the product mold in production to aid in the cooling process in manufacturing.

Why should I use the J instead of a strap?

How far apart should I hang the J?

The Air Diffusion Council recommends that flexduct hangers be spaced no more than 5 feet apart with no more than 0.5" of sag between hangers.

Will this product crack in the cold like other plastic products?

No, the H is made of a High Impact Polystyrene and the J of a CoPolymer Polypropolene... both have been tested for cold, heat, and UV resistance.

Are these products UL or NFPA certified?

Both the H and J have been presented to UL (Underwriter's Laboratory) and NFPA (National Fire Protection Association). Because the products play a supportive role not central to the transfer of heated or cooled air, certification is not necessary.